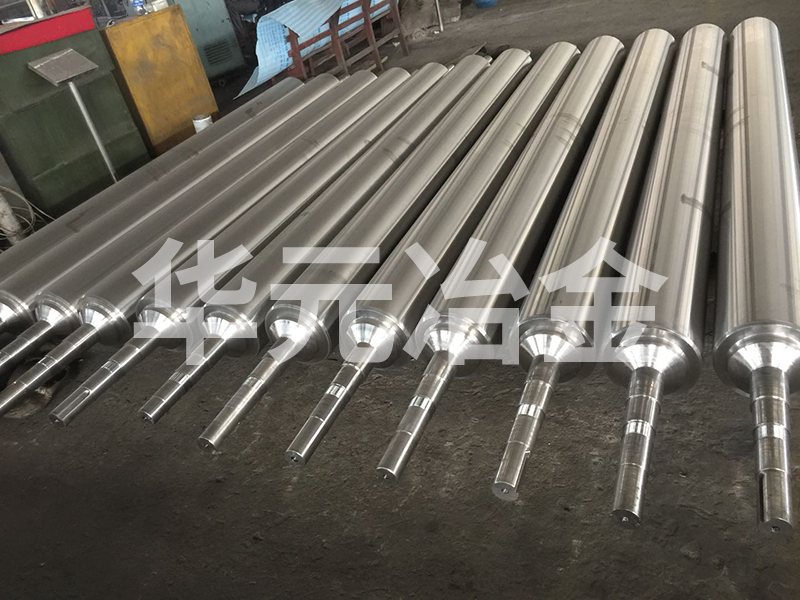

Bottom roller is an indispensable processing equipment in the steel plate smelting production process. In order to ensure the requirements of steel plate production, the bottom roller also has high requirements for use. The hearth roll is a typical centrifugal casting pipe fitting, one of the important parts for supporting and transporting slabs in metallurgical equipment, and is widely used in steel plate continuous casting and rolling production lines.

In the rolling process, the steel slab must be continuously and stably heated to a rolling temperature of 1050 to 1150°C in the heating furnace, and the slab can be stably supported by the furnace bottom roller to ensure smooth and uniform transportation. Since the middle section of the hearth roll is directly installed in the billet calciner, the furnace gas temperature is as high as about 1150°C during the production process, and it is usually made of high-temperature alloy materials such as ZG45Cr28Ni48W5Si2. At the same time, because the supporting part in the middle of the bottom roller is directly installed in the furnace, and the cone section and the bearing support part are installed in the furnace wall and outside the forging furnace, respectively, the temperature gradient of different parts of the bottom roller is very large, so The bottom roller is generally formed by welding the cylinder, cone and shaft to each other. In order to reduce the burning damage to the inner surface of the cone, a heat insulation board is designed inside the cone. In order to ensure the smooth transportation of high-temperature slabs, it is required that the roller shaft is not deformed and the outer roller ring is heat-resistant and wear-resistant.

Now that everyone understands the application of furnace bottom rollers in metallurgy, it can only be used better if they understand their role. In addition, in order to ensure good performance of the hearth roller and prolong the service life, regular inspection and maintenance are required.

為您提供耐腐耐磨砂漿泵,工程塑料泵,蒸發循環泵等方面的專屬解決方案

08

20-08

1.采用輻射管加熱的無氧化(氮氣保護)輥底式熱處理爐(常化爐),使用一段時間,爐輥爐底輥結瘤,結瘤的直接危害是使較厚的鋼板產生麻坑而影響表面質量,如下圖所示,請大家談談預防爐底輥結瘤的有效措施以及結瘤后的處理辦法。2.澆鑄的在組織密度上存在氣孔,砂眼等先天不足···

08

20-08

離心鑄造件的表面會有一層涂料,這是為了使工件獲得最佳的狀態。而關于離心鑄造件涂料的操作流程,又有所少人了解呢?以下就是與之相關的基本內容。在鑄造工件的時候,需要先烘烤鑄模,將會其中的水汽去除掉并且通過提高模溫來防止爆炸飛濺。烘烤可用噴燈或紅鐵塊等方式來操作,而···

08

20-08

爐底輥是鋼板冶煉生產過程中必不可少的加工設備,為保證鋼板生產的要求,對于爐底輥也具有較高的使用要求。爐底輥是一種典型的離心鑄造管件,是冶金裝備中支撐和輸運板坯的重要部件之一,在鋼板連鑄連軋生產線中應用廣泛。軋制成過程中,首先需要將鋼坯在加熱爐中連續穩定加熱至1···

08

20-08

推導了連退爐內爐輥爐底輥為錐度輥時的帶鋼對中力的表達式,分別介紹總結了帶鋼對中運行及瓢曲變形的機理。在此基礎上,分析了爐輥爐底輥種類、爐輥爐底輥形狀參數、爐輥爐底輥表面狀態及爐輥爐底輥熱凸度對帶鋼高速通板技術的影響,并提出了爐輥爐底輥選擇和優化設計的指導原則,···